Pentaflex Sinuga N

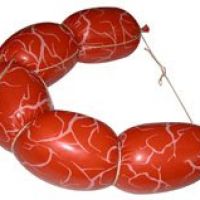

- is a multilayer poliamide casing, packed in Pentaflex-Sinuga®, is very similar to products in natural casing, excluding at the same time all defects of natural sinuga.

SCOPE OF USE:

• poultry sausages;

• staffed sausages.

FEATURES AND BENEFITS:

Appearance of sausages and hams, packed in polyamide casing Pentaflex-Sinuga®, is very similar to products in natural casing, excluding at the same time all defects of natural sinuga. Undoubted advantage - forcemeat capacity (30-35%), which allows to meat products producers get a very similar appearance with natural casing and at the same time considerably cut down expenses for packing.

Benefits:

• high barrier properties;

• elasticity;

• mechanical strength;

• biological inertness;

• heat resistance;

• increase shelf-life of products.

Calibers:

| Caliber, mm | Caliber, mm |

| 65 | 85 |

| 80 | 104 |

Offered color spectrum: brown (S-01-03), transparent (S-01-01); smoky (S-01-02).

Term of storage of products in casing

Products, packed in Pentaflex-Sinuga® casing, have shelf-life up to 60 days (by temperature interval +2°C-+6°C), which is confirm by the results of researches and by the State sanitation service, given in Ukraine and Russia.

Recommendation on application

Storing at the production facilities

They should be handled with caution and proper care to avoid hitting and falling down.

Casing is frostproof, stand temperature -20°C.

Casings that have been stored at temperatures lower than 0C should be kept at a room temperature for not less than one day before using.

Preparation of Casing for production of sausages

During preparation of casing for production process, when a reel of casing is unwinding and being cut into pieces, it is necessary to monitor side parts of the reel and surface of the casing sleeve to prevent them from rubbing against various types of uneven or rough surfaces. It is recommended to unwind the reel of casing in the vertical position.Before using Pentaflex- Sinuga® casing should be cut into pieces of required length, soaked in water at the temperature +18+25°C and kept there for 30 minutes. It is completely forbidden to soak the casing in hot water. For the purposes of evenness of soaking process, it is obligatory that during submerging in the water one end of each casing piece should be open to secure soaking of an internal surface of casing as well. During soaking casings have to be under the water. With that purpose it should be covered (pressed) by frame and kept during 30 minutes. It will considerably increase its elasticity, facilitate process of stuffing and ensure uniformity of filling forcemeat over the full length of a sausage stick.

In case of using the shirred casings, it is necessary that shirred sticks be submerged completely into the water at a temperature of 18-25C and kept there for at least 40 minutes.

Consumption of the casing should be calculated for the volume of sausage production. In case there is some casing left after production, it should be left in cold water and used within 24 hours.

Recommendations on technological peculiarities of sausage production process using polyamide ring casings

Technological process of sausages’ production should be implemented in strict conformity with the acting technological instruction.Due to the gas and moisture impermeability of Pentaflex-Sinuga® casing, no losses of humidity is observed at thermal treatment of sausages; that’s why the amount of water, added to sausage meat when it is chopped should be decreased to 5-10%. This will allow to exclude the formation of bouillon and fat substances and breaking of the casing during thermal treatment, and the planned output of the finished products will not change. The use of additives when making boiled force meat in polyamide casing requires special attention in further cycles of technological process.

Increase of water-retaining quality of meat leads to intensive swelling of proteins, which facilitates increase of internal pressure of force meat of the sides of the casing during thermal treatment.

Therefore the observance of required recommendations on application of additives, stepped thermo treatment of sausages will allow to exclude the breaks of sausages during cooking.

Stuffing of casings

The filling of casings is recommended to perform with overstuffing by caliber within the limits of recommended staffing diameter (RSD) of 30-35% (for instance, when the 80 mm caliber of casing is used it is recommended that stuffed sausage stick reach up to 104-108 mm in diameter). Chosen percentage of overstuffing has to be unchanged during entire stuffing process, the stuffing must be compact along the whole length of a sausage stick. Control of overstuffing diameter realize by the force of measuring stick diameter by caliber-roll.In case of observance of all requirements is ensured the presentable appearance of sausages, increased forcemeat capacity, excluded possibility of fat formation.

Clipping of casings

Pentaflex-Sinuga® casing can be used in production process involving usage of both automatic ("ALPINA", "POLI-CLIP", "TEHNO-PACK") and semi-automatic types of equipment, as well as for clipping manually.When clipping, it is necessary to pay attention to regulating of clipper, the right choice of clips that corresponds to the type of the casing and diameter. Clips should ensure firm clipping of the ends of the casing, so that clips do not move and damage the casing. The internal diameter of sausage sticks’ rings amounts to 160-180 mm.

Thermal processing

Thermal processing of sausages should be performed according to the current technological instructions by scheme:Heating - Cooking - Showering – Cooling in the chamber.

Due to gas impermeability of the casing, the process of frying is excluded during thermal treatment. It should be taken into account that by excluding the process of frying, it is absolutely necessary to use by-stage boiling, to begin the increase of temperature starting from +55+60°C, which will ensure the process of colour formation. For example for casing O65 mm thermal treatment is next:

- 55C in heat-chambers at 100% humidity-15min;

- 65C in heat-chambers at 100% humidity -20min;

- 75C in heat-chambers at 100% humidity -30min;

- 80C in heat-chambers at 100% humidity to temperature inside the stick 72C;

Last stage of thermal treatment – is boiling process, driving the product to preparedness (72C in the centre of stick during 10-15minutes). Number of stages of rising temperature will depend on diameter of the sticks, the bigger diameter, the more stages.

Duration of stages of heating are chosen by the company, depending on technological demand and equipment abilities. It is forbidden to cool sausages with cold air after cooking, it may lead to formation of wrinkles. It is necessary to exclude draughts until sausages don’t cool off.

It is possible to cook sausages in boilers.

During the process of cooking sausages in boilers, please observe the requirements of technological instruction and recommendations on casing application:- The sticks are put into boilers with water temperature at +55+60°C;

- It is completely forbidden to put the sticks into the water with the boiling temperature +80°C. This could lead to early shrinkage of the casing and deformation of the sticks;

- The sausages must be fully covered by water;

- The temperature must be increased gradually and with intervals;

- When putting the next lot of sausages, the water temperature should be controlled, which should not exceed +60°C;

- The readiness of sausage is characterized by the temperature inside the stick at +72°C.

Cooling

After the cooking sausages should be cooled in two stages.

Stage 2 – after cooling under the shower, sausages dry at natural temperature and then they are taken to a cooling camera with temperature at +4+6°C.

Cooling of the product with intervals ensures simultaneous and even shrinking of the casing and force meat, which excludes the possibility of wrinkles on the surface of a sausage stick

Slicing and removing the casing off the sausage stick

Pentaflex-Sinuga® casing is very easily removed off a sausage stick. After removal, the surface of the product remains smooth and glossy.In order to prevent tearing and decrease the tension on the casing during cutting of sausages, it is advisable to cut both clips first.

Packing and storing of the sausages

After the cooling sausage sticks are transferred to the storage facilities for storing and selling. Temperature in the storage area should be set according to the requirements specified in the technological instruction for production of the given type of product.Sausage sticks with the clean and dry surface are packed in the sanitized containers not exceeding their weight capacity and shipped for sale. During the storing, sharp changes in temperature are unacceptable to exclude possibility of appearance of condensation moisture on the sausage sticks’ surface.

In the retail the sausage sticks should be taken out of shipping containers and stored into the refrigerators, showcases and so on.