- Cooked and cooked smoked sausage products

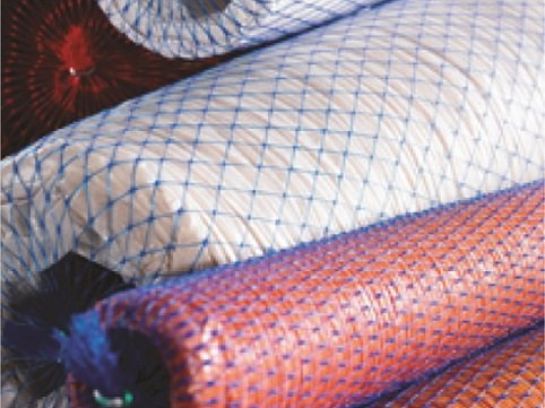

- Raw sausage products, curve-shaped (such as “Mergez“ sausages, Cumbrian sausages, Ukranian fried sausages) to grill or freeze later on.

SCC

SCC - edible collagen casing, curve-shaped.

SCC - edible collagen casing, curve-shaped.

SCOPE OF USE:

FEATURES AND BENEFITS:

- Shape stability (stable caliber and weight while stuffing, heat treating and storing)

- Usage on all kinds of equipment (high mechanical strength and elasticity)

- Ring-like shape, exactly imitating a natural casing

- High stuffing capacity

- The casing does not require soaking (time consuming while cooking)

- The casing is more hygienic in comparison with a natural casing

- BRC, ISO Standards Certification

- In complience with Halal, Kosher requirements

- Manufactured in Serbia at Koteks manufacturing facility

SCC - is used for manufacturing of cooked and cooked smoked sausage products of a curved shape.

Calibers:

SCC: 19-25 mm (19 / 21 / 23 / 25)

Shirring

Variants of shirring of a casing in 1 core from 27 ft.( 8,2296 m) to 60ft. (18,288 m)are available.

Depending on a stuffing equipment, cores can have special types of ends:

OE- open end

CE- closed end

Knot- узел

Colors: transparent

Preparation

SCC casings can be used without any preparation.

Avoid moisture loss. Stuff within the bounds of the recommended diameter.

Recommendations on stuffing:

|

Nominal caliber |

Recommended caliber of stuffing, mm |

Recommended nozzle, mm |

||

|

19 |

19 |

+/- |

0,5 |

11 |

|

21 |

21 |

+/- |

0,5 |

12 |

|

23 |

23 |

+/- |

0,5 |

13 |

|

25 |

25 |

+/- |

0,5 |

15 |

|

28 |

28 |

+/- |

0,5 |

16 |

|

30 |

30 |

+/- |

0,5 |

17 |

|

32 |

32 |

+/- |

0,5 |

20 |

|

34 |

34 |

+/- |

0,5 |

21 |

|

36 |

36 |

+/- |

0,5 |

23 |

|

38 |

38 |

+/- |

0,5 |

23 |

|

40 |

40 |

+/- |

0,5 |

23 |

|

43 |

43 |

+/- |

0,5 |

27 |

Recommendations on heat treatment of SCC:

| Step |

Temperature in a chamber (°C) |

Humidity (%) |

Temperature in a stick center (°C) |

Duration (min) |

|

1. Precooking 1 |

50 |

95 |

|

20 |

|

2. Preccoking 2 |

60 |

80 |

|

10 |

|

3. Drying |

65 |

|

|

10 |

|

4. Smoking |

65 |

75 |

|

10 |

|

5. Smoke extraction |

68 |

|

|

2 |

|

6. Cooking |

76 |

99 |

72 |

|

|

7. Spraying |

By cold water for 3 minutes, then 2 minutes break. Repeat several times |

|||

Recommendation on heat treatment of SCC-B for its usage for heat treated product manufacturing to fry later on.

It is recommended to hang the product on frames not mote than 2+2 (for calibers from 26). If possible, use the lowest speed of chamber ventilators rotation.

|

Step |

Temperature in a chamber, ⁰ С |

Duration, min |

|

Drying |

60 ⁰ С |

15-20 min (depending on a caliber) |

|

*Smoking |

65-70 ⁰ С |

15-20 min (depending on a color required) |

|

Drying |

65-70 ⁰ С |

5 min |

|

Cooking |

max.76 ⁰ С |

up to 72 ⁰ С in a stick center |

|

Spraying/ cooling |

|

By cold water for 3 minutes, then 2 minutes break. Repeat several times. |

*this step is optional, depending on an end product