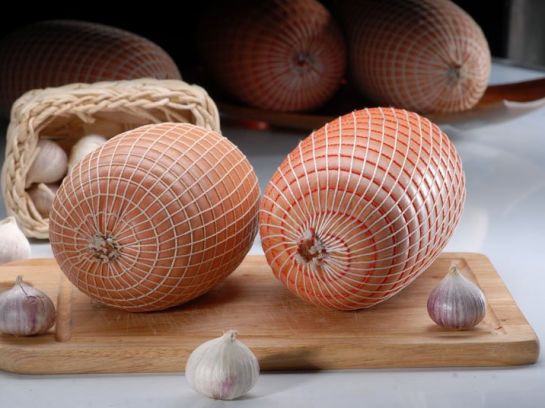

- Cooked sausages;

- Hams.

Cellophane

Cellophane cellulose casing is a multi-layer sausage casing in cuts, produced on the basis of cellulose film in rolls. The casing is formed on special cylinder forms, the layers of which are joined together by the food glue.

SCOPE OF USE:

FEATURES AND BENEFITS:

- Excellent translucency and glos;

- Ensures an attractive and natural layout and taste of the end product;

- Has antistatic properties: is easily pelled off, prevents a condensate depositio;

- High mechanical strength and elasticity;

- Vapor-, gas-, moisture permeabilit;

- Possibility of forming on all kind of stuffer;

- Stable caliber while heat treating and storing;

- Achievement of high flavor and aroma properties while heat treating and smoking;

- Preservation of the aroma of a product during all term of storage.

Most popular calibers: 65,80,85,110 mm

Standard quantity of layers: 3 or 4

Delivered

in cuts by 400,480,550 mm

Marking

by means of a strip-label, laid along the sleeve between the layers. The material of a label can be moisture proof parchment, soloset or polypropylene. One-colored or two-colored printing can be applied onto the label upon the request of the customer.

Stage I. Preparation

Cellulose film is ready to use without preliminary preparation. Cellophane cellulose casing can be used without preliminary preparation ot to be exposed to soaking by means of dipping into water immediately before forming.

Stage II. Stuffing

Casing cuts are stuffed by hand, while regulating the casing running off from the spindle by the thumb. Method of tying in this case depends on the casing's diameter and weight of the a stick: the heavier the stick- the stronger the tying should be. Stuffed sausages are tied by the string using several bindings and are clipped. Formed sticks are hanged up onto vertical or laid down onto horizontal frames. The diameter of stuffing depends on a process and the required diameter of the product. It is better to perform the forming of the casing with overstuffing up to 5% from its nominal diameter. Maximum length of the end product should not exceed 20 cm to avoid breaking of the casing next to upper clip and lost of its homogeneous form.

Stage III. Clipping

The casing is clipped an all types of clippers, is formed manually.

Stage IV. Heat treatment

For big calibers (80 mm and more) most suitable are those heat treating regimes that are used while manufacturing of the sausages in beef middles. As cellulose is a heat treating proof metarial, it is allowed to use обработке изделий high temperature regimes while heat treating up to 100°С, thus guaranteeing well cooked end product.

| PROCESS | Temperature in a chamber,°С | Temperature inside a sausage, °С |

Duration, min |

Relative humidity, % |

| drying | 55-60 | ----- | 70-80 | ----- |

| roasting | 80 | ----- | 15-20 | ----- |

| smoking | 80 | - ---- | 20-25 | 70-80 |

| cooking | 80 | up to 72 | 60-65 | 99-100 |

Stage V. Cooling

Spraying by cold water at temperature 10-12°С for 30 minutes.

Conditions of storage

It is required to store the film and the casing in a package in closed, clean and dry premises odour free, protected from sunlight, at the distance not less that 1 m from heaters, at temperature 17-23 °С and relative humidity 35-55%. It is required to leave the casing in the premises at room temperature for 24 hours before use.

Terms of storage

24 months from the date of manufacturing at the condition of manufacturing package integrity and conditions of storage observance.