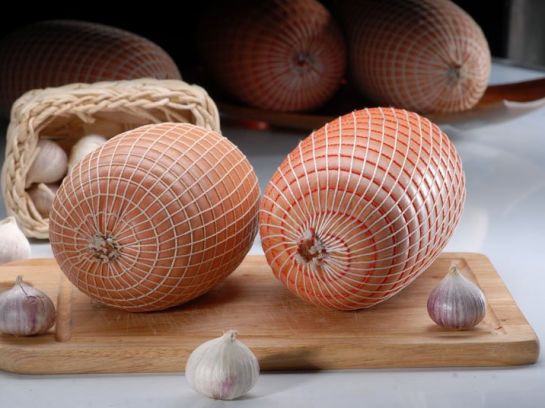

- Smoked delicatesse;

- Meat nuts;

- Hams, rolls;

- Smoked fillet steak;

- Fish products.

Cellulose film

Cellulose film - is a film produced from the raw material of plant origin (cellulose from tree species of wood, cotton, etc.) with high level of decontamination.

Cellulose film - is a film produced from the raw material of plant origin (cellulose from tree species of wood, cotton, etc.) with high level of decontamination.

SCOPE OF USE:

FEATURES AND BENEFITS:

The main advantage of this film during the production of delicatesse products is the achievement of high flavor and aroma characteristics owing to good vapor, gas and moisture permability.

Cellulose film gives the end product excellent market conditon, and also decreases weight loss, which can occur due to intense evaporation during cooking and smoking. The film has antistatic qualities. The film is easily torn off, prevents from the sedimentation of a condensate ; both of her sides are excellently printed with different colorants.

Bearing in mind all its advantages, cellulose films are comparably non-expensive.

Use of cellulose film does not require limitation of smoking and cooking process and when needed lets remove the net without efforts, not breaking the product surface. It is possible to cut the end product into lovely slices.

Cellulose film does not require an additional preparation and soaking.

It is possible to use manual and automatic applicators for the production of smoked products using this film.

During work it is required to limit the contact of the film with moisture.

The time of thermal processing is chosen in accordance with the technological process, provided for different kind of delicatesse products.

Cellulose film should be stored in the place covered and protected from heaters and sunlight.

Recommended conditions of storage:

Temperature: 17-23ºС

Humidity: 35-55%