Logoline

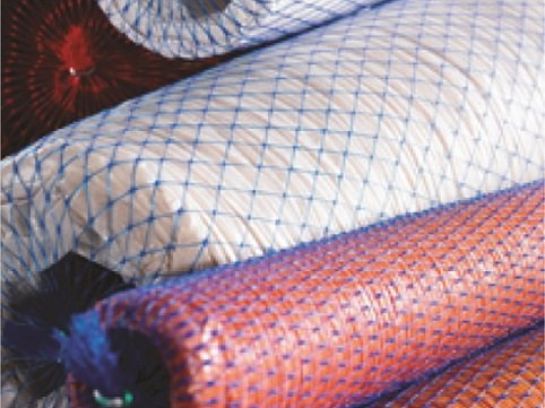

- are non-edible one-layer polyamide casings, produced on modern equipment, ensuring a constant control under all the parameters and maximum automatization of a manufacturing process.

LOGOLINE is a barrier casing, aimed at manufacturing of all kinds of sausages, wieners, mini-sausages.

SCOPE OF USE:

FEATURES AND BENEFITS:

PROPERTIES:

High mechanical strength and elasticity

High barrier properties

Vapor-, gaz-, moisture permeability

ADVANTAGES:

Possibility of usage on all types of equipment and of hand tying

Stable caliber while stuffing, heat treating and storing

Attractive outlook of the end product during all the term of storage

Prolonged term of storage of the end product

Preservance of the aroma of sausage products

Protection from odors penetration

Minimal losses while heat treatment and storing

Stable output of the end product

COLORS: translucent, light smoke, smoke, dark smoke, pink

CALIBERS: 22, 24 mm

DELIVERED in shirred strands with closed endMARKING is made in accordance with the Client's request

Stage I. Preparation

Open the casing immediateky before use. The casing is ready without preliminary preparation for using on automatic sausage lines. While using on twisters the casing should be soaked in pure water at temperature 25-30°С for 30-60 minutes.

(!) TO AVOID SHRINKING OF THE CASING DO NOT SOAK IN HOT WATER

Shirred casing should be fully positioned under the water. After soaking remove the surplus water from shirred reel and put on a twister's spindle. It is necessaty to store opened and non-used casings in a cold premises, far from the heaters and draughts. If used for the second time - repeat soaking, while dipping the casing into the water.

Stage II. Stuffing

Shirred casing is put on the spindle "herringbone" inside, that means the top of "herringbone" is directed to the twister.

Speed regime of stuffing is designated depending on technocal condition of the equipment.

While forming of the product it is necessary to mention that a real caliber of stuffing is designated by different factors such as product type, farce temperature and consistency, condition of the equipment.

(!) IT IS STRICTLY PROHIBITED TO STRICK SAUSAGES AND WIENERS

|

Nominal caliber [mm] |

22 |

24 |

Caliber after stuffing [mm]

|

24 |

26 |

|

While manufacturing of sausage products it is necessary to decrease the quantity of the water added for the quantity of moisture loss during heat treatment, considering barrier properties of the casing. This will let to avoid the formation of water and fat pockets. raptures of the casing while heat treatment, and planned output of the product will not change. Usage of additives while composing the farce requires a special attention for the following cycles of technological process. Increase of moisture retaining capacity of meat will lead to intense swelling of proteins, what provides for inner pressure increase of farce to the walls of the casing during heat treatment. Heat treatment is made both in stationary chambers of shaft type and in universal chambers. Regime of heat treatment is chosen by a manufacturer individually depending on the equipment capacities.

Example of heat treatment of the products in LOGOLINE casing, caliber 24 mm:

| PROCESS | Temperature in a chamber,°С |

Temperature

inside a sausage, °С |

Duration, min |

Relative humidity, % |

| Cooking stepwise | ||||

| I step | 55 | ----- | 10 | 100 |

| II step | 65 | ----- | 15 | 100 |

| III step | 75 | ----- | 15 | 100 |

| IV step | 80 | up to 72 | 15 | 100 |

Stage V. Cooling

Spraying by water until temperature 25-35°С inside a sausage.

(!) IT IS NECESSARY TO AVOID HERMETIC PACKAGING DAMAGE

It is required to avoid draught influence to the end product until complete cooling, because it may lead to wrinkles formation.

Conditions of storage

It is necessary to store the casing in an oroginal package in closed, clean, dry premises free from odours, protected from sunlight, at the distance more than 1 m from heaters, at temperature not above 25°С and relative humidity not above 65%.

(!) It is prohibited to throw and subject to hit boxes with a casing

It is required to keep the casing, which was exposed to low temperatures, at room temperature before use for not less than 24 hours before opening of the packaging.

Terms of storage

12 months from the date of manufacturing at condition of preserving of packe integrity and observance of conditions of storage.